Aluminum Alloy Side Pressure Window

Send Inquiry

Product Features

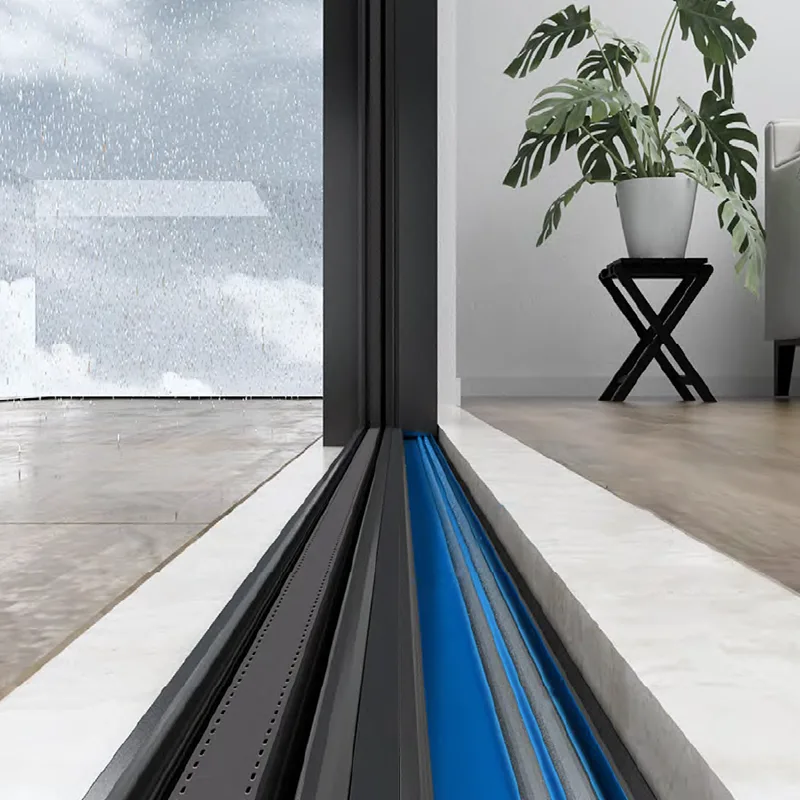

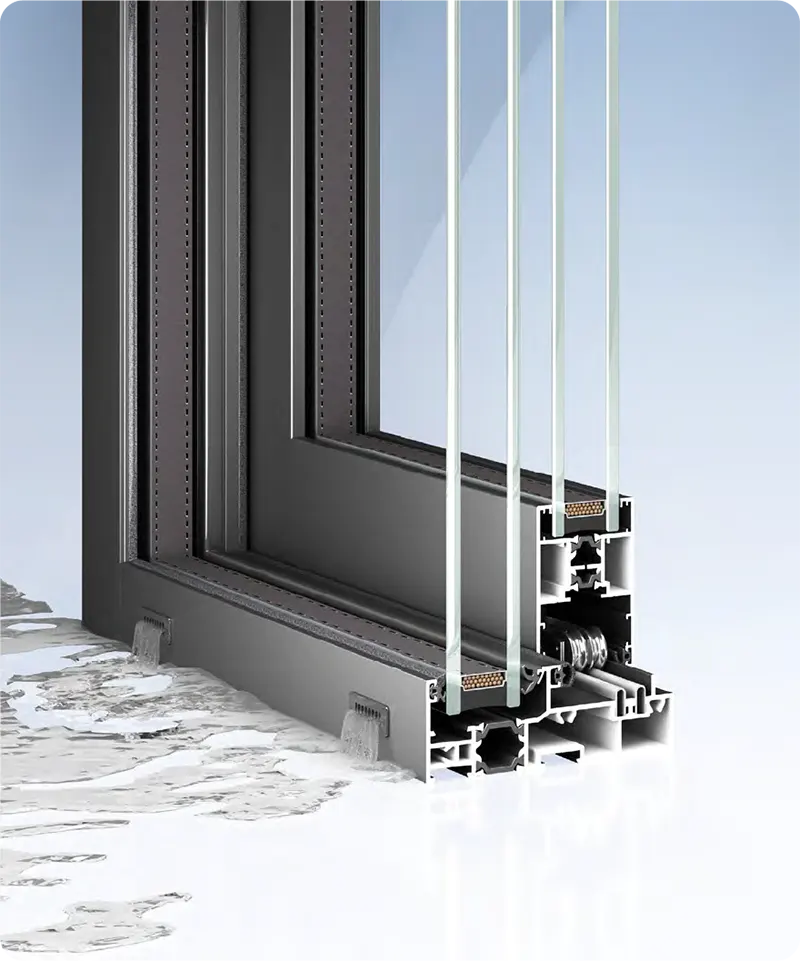

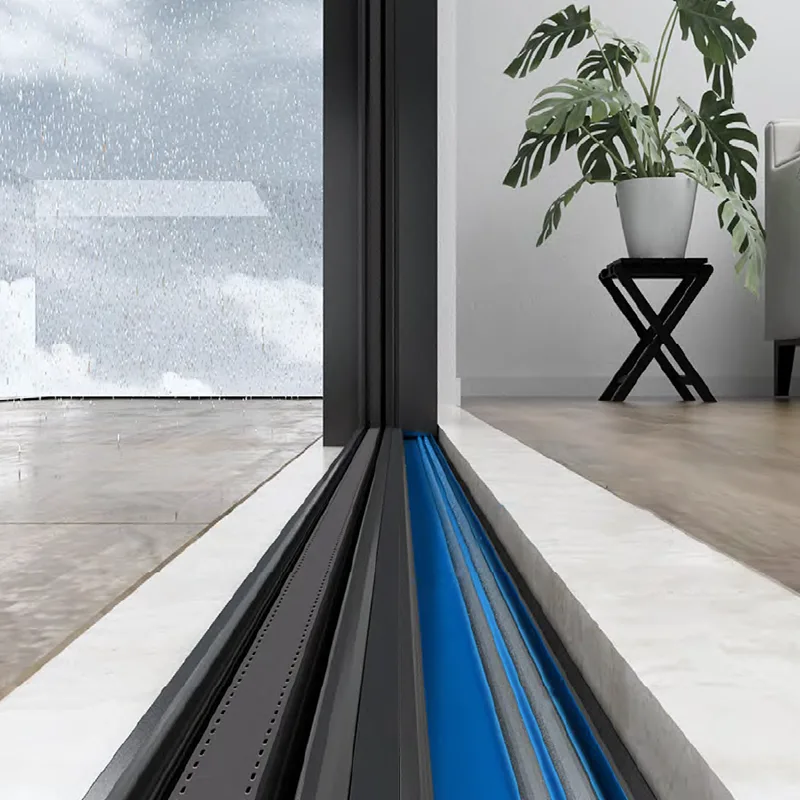

1. The Aluminum Alloy Side Pressure Window adopts a floor drain-type stepped drainage structure to avoid the drainage hole directly facing the air outlet, reduce the possibility of rainwater backflow, and more directly and effectively discharge rainwater to the outside.

2. The 304 stainless steel track is matched with a high-load-bearing 120kg pulley, which is smooth and unobstructed, smooth and light, noise-free and light and flexible.

3. The heat insulation strip is installed between the hooks and the platform to effectively improve the sealing and sound insulation ability of the broken bridge side pressure window, and reduce the noise and damage to the window sash caused by collision when closing.

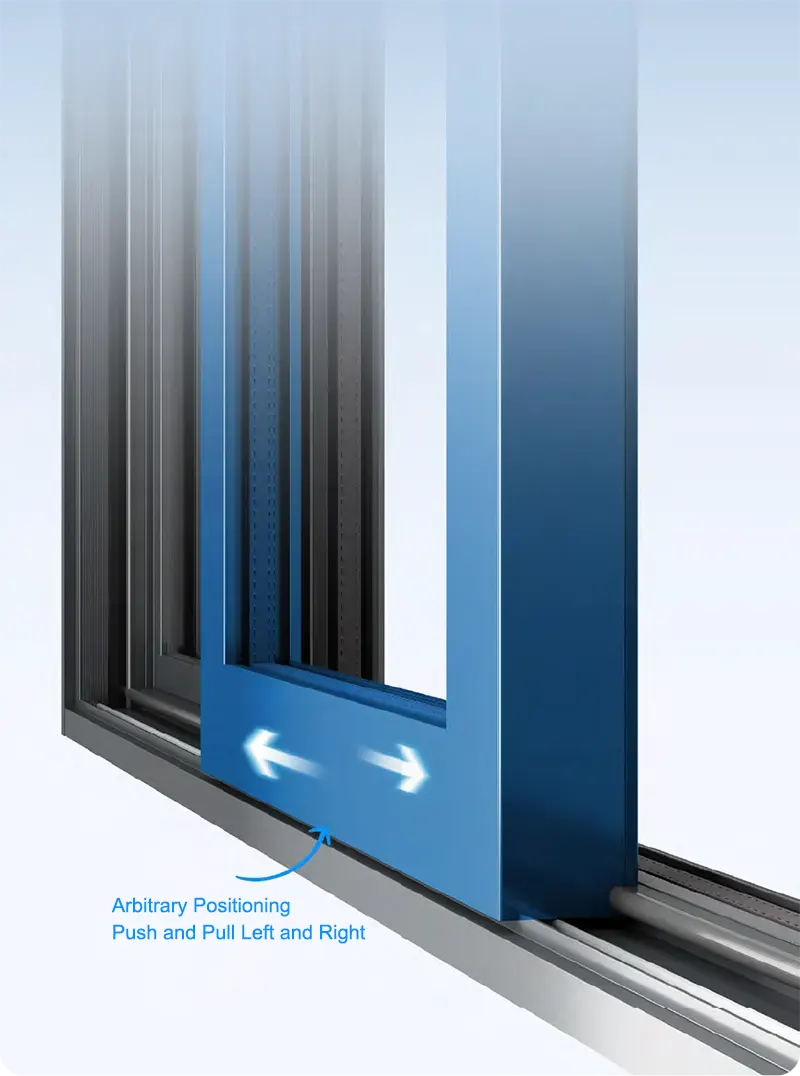

4. The use of high-quality 304 stainless steel tracks and a single-leaf two-slide design is conducive to dispersing pressure and evenly pushing and pulling forces, making the Aluminum Alloy Side Pressure Window lighter to push and pull, higher load-bearing, and lighter to slide.

5. The innovative and strengthened middle stile design of the broken bridge side pressure window makes the window strong and non-deformed, resists the challenges of various severe weather, and protects the safety of the family from intrusion.

6. The movable sliding fan can be moved horizontally in the room to avoid the safety hazard of falling off during use and installation. It has good extrusion sealing effect and strong sound insulation.

Product Specifications

|

Standard hardware |

Customized hardware |

|

Glass configuration |

5mm+20A+5mm |

|

Profile wall thickness |

1.8mm thick 6063-T5 aluminum profile |

|

Profile width |

110mm |

|

Insulation tape width |

14.8mm wide PA66 single cavity insulation strip |